In the era of rapidly advancing technology, industries are constantly seeking ways to enhance efficiency and accuracy in their processes. One area that has seen remarkable progress is visual quality control, thanks to the integration of artificial intelligence (AI) systems. From manufacturing to automotive, pharmaceuticals to electronics, AI-powered visual inspection is transforming how defects are identified and rectified. Let’s delve deeper into this groundbreaking application of AI.

Understanding Visual Inspection AI

Visual inspection AI, also known as AI-based visual inspection or AI visual inspection system, refers to the utilization of AI algorithms to automate the process of inspecting and analyzing visual data for defects or anomalies. This technology employs computer vision techniques to mimic human visual perception and decision-making capabilities, enabling it to detect even the slightest deviations from the desired standard.

Enhanced Accuracy and Consistency

One of the primary benefits of employing AI in visual inspection is its unparalleled accuracy and consistency. Unlike human inspectors, AI systems do not suffer from fatigue or subjective biases, ensuring that every component or product is scrutinized with the same level of precision, regardless of the time of day or environmental factors. This consistency leads to improved quality control standards and fewer defects escaping detection.

Speed and Efficiency

AI visual inspection systems are capable of processing vast amounts of visual data in a fraction of the time it would take a human inspector. This rapid analysis results in faster production cycles, reduced inspection times, and ultimately, increased throughput. Manufacturers can identify and address defects promptly, preventing them from escalating into costly issues downstream.

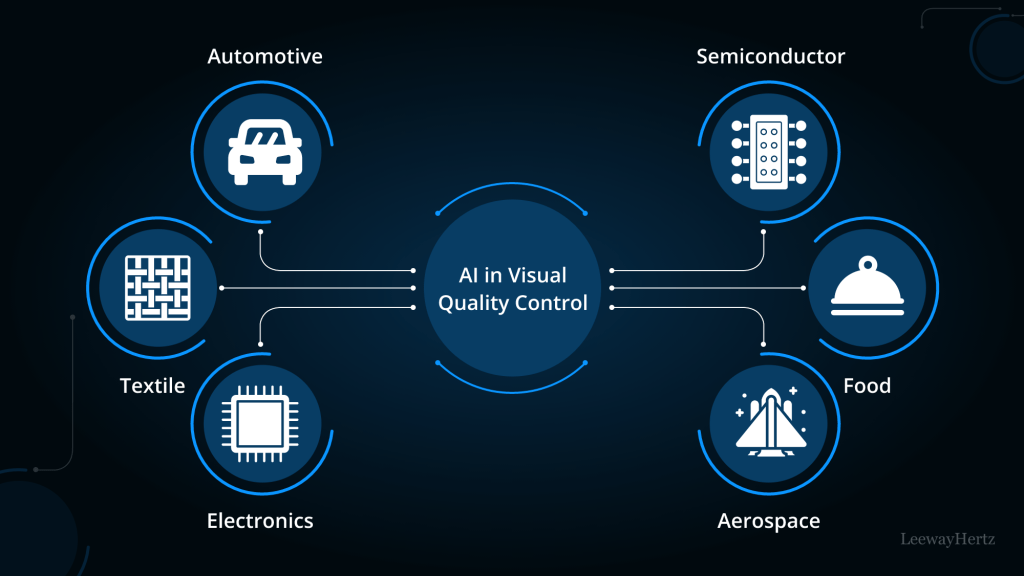

Adaptability to Diverse Applications

Another advantage of AI in visual inspection is its adaptability to diverse applications and industries. Whether it’s identifying surface defects in automotive components, ensuring the integrity of pharmaceutical tablets, or inspecting circuit boards for soldering flaws, AI systems can be trained to recognize specific defects unique to each application. This flexibility makes them invaluable across various sectors, facilitating a wide range of quality control tasks.

Continuous Learning and Improvement

AI-powered visual inspection systems are not static entities but rather dynamic tools that continuously learn and improve over time. Through techniques such as machine learning and deep learning, these systems can refine their algorithms based on feedback from previous inspections. This iterative learning process enables them to adapt to evolving production environments and detect previously unseen defects with greater accuracy.

Cost Savings and ROI

While the initial investment in AI visual inspection technology may seem significant, the long-term cost savings and return on investment (ROI) are substantial. By reducing the need for manual labor, minimizing defect-related rework, and preventing product recalls, manufacturers can achieve significant cost efficiencies and enhance their bottom line. Moreover, the improved quality and consistency resulting from AI-driven inspections can bolster brand reputation and customer satisfaction, further contributing to ROI.

Challenges and Considerations

Despite its numerous benefits, implementing AI in visual inspection is not without its challenges. Ensuring adequate training data, addressing class imbalance, and mitigating the risk of false positives/negatives are some common hurdles that organizations may encounter. Additionally, integrating AI systems into existing production workflows and ensuring compatibility with existing hardware and software infrastructure require careful planning and coordination.

The Future of Visual Inspection

As AI technology continues to evolve, the future of visual inspection holds immense promise. Advancements in machine learning algorithms, sensor technology, and robotics are poised to further enhance the capabilities of AI visual inspection systems. From real-time defect detection to predictive maintenance, the possibilities are endless.

In conclusion, AI-powered visual inspection represents a paradigm shift in quality control methodologies, offering unparalleled accuracy, speed, and adaptability. By embracing this transformative technology, industries can elevate their quality standards, streamline production processes, and drive innovation in the global marketplace.

Leave a comment